Electronics accessories

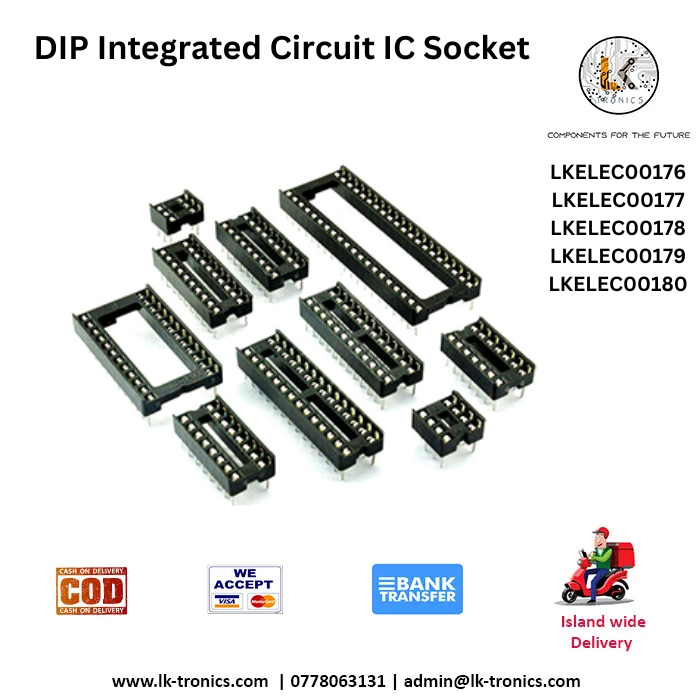

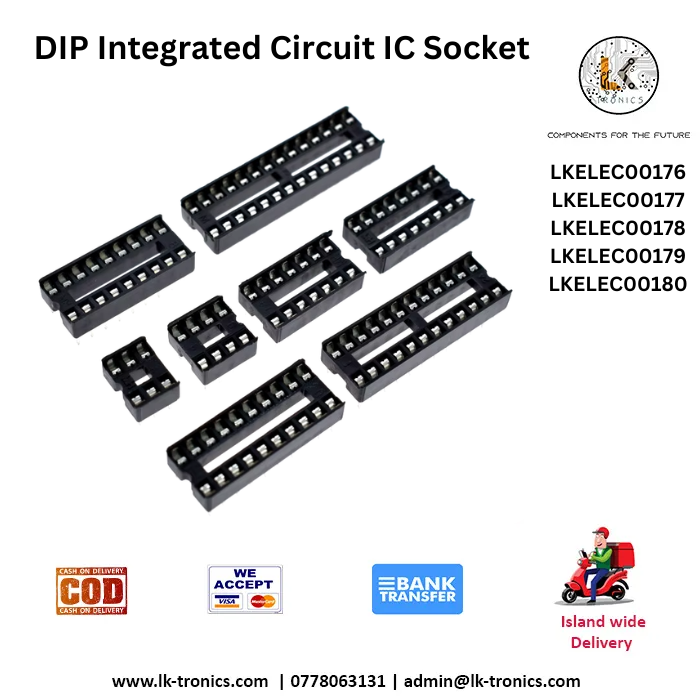

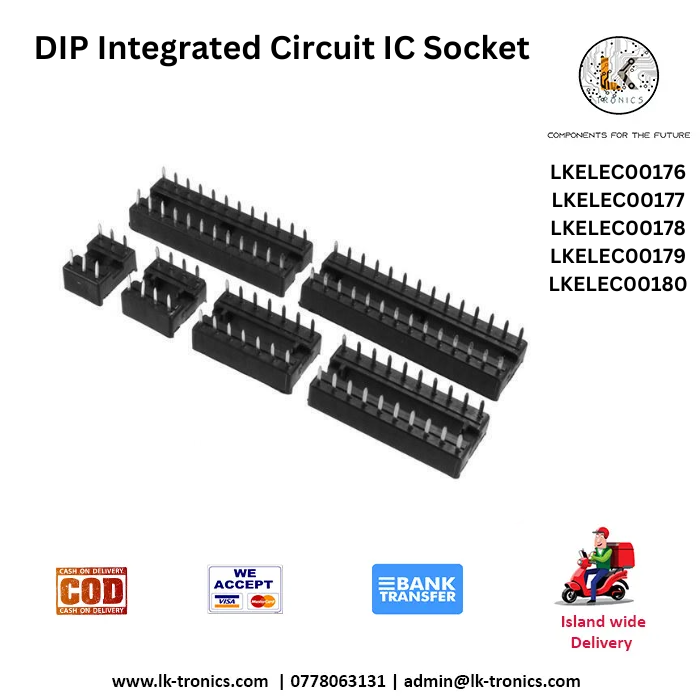

DIP Integrated Circuit IC Socket

Availability:

In stock

LKELEC00176| LKELEC00177 | LKELEC00178 | LKELEC00179 | LKELEC00180

Rs 10.00 – Rs 32.00

CompareDIP Integrated Circuit IC Socket

The DIP Integrated Circuit IC Socket provides a reliable connection for DIP package components, making it easier to replace and protect ICs in your projects. This socket ensures a secure and durable connection, ideal for prototyping and circuit assembly.

Specifications

1. Pin Count:

- Range: Typically available in pin counts, including 6, 8, 14, 16, 18, 20, 24, 28, 32, 40, 48, and 64 pins.

- Selection: The pin count should match the IC being used.

2. Contact Type:

- Material: Commonly made from phosphor bronze, beryllium copper, or tin-plated steel.

- Plating: Gold or tin plating is often used to improve conductivity and corrosion resistance.

3. Pitch (Pin Spacing):

- Standard: 2.54 mm (0.1 inches) between the center of each pin.

- Width: The width between rows of pins is typically 7.62 mm (0.3 inches) for narrow sockets and 15.24 mm (0.6 inches) for wide sockets.

4. Mounting Style:

- Through-Hole: DIP IC sockets are usually through-hole mounted, meaning the pins pass through the PCB for soldering.

- Solder Tail Length: Varies, but commonly ranges from 3 mm to 4 mm.

5. Profile:

- Low-Profile: Designed to minimize height above the PCB. Typically, low-profile sockets have a height of about 2.54 mm (0.1 inches).

- Standard Profile: Generally taller, with a height of around 3.56 mm to 5 mm.

6. Insulator Material:

- Material: Most sockets are made from thermoplastic or thermosetting polymers like polyester, PPS (polyphenylene sulfide), or PBT (polybutylene terephthalate).

- Temperature Rating: Most materials typically operate between -55°C to 125°C.

7. Operating Voltage:

- Rating: Varies based on the material and pin configuration, but commonly around 100-500V.

- Dielectric Strength: Typically around 1000V AC for 1 minute.

8. Current Rating:

- Typical: Ranges from 1 A to 3 A per pin, depending on socket design and materials.

9. Insertion and Extraction Force:

- Insertion Force: The force required to insert an IC into the socket ranges from 1 to 3 N per contact.

- Extraction Force: The force needed to remove an IC from the socket is typically 0.5 to 2 N per contact.

10. Contact Resistance:

- Standard: Generally less than 20 mΩ, depending on the contact material.

11. Durability (Mating Cycles):

- Typical: Around 10-50 mating cycles, though some high-end models can withstand up to 200 cycles.

VISIT OUR FACEBOOK PAGE FOR MORE INFO | MORE PRODUCT IN OUR SHOP

| Type | DIP-6P, DIP-16P, DIP-18P, DIP-20P, DIP-24P |

|---|

Based on 0 reviews

Be the first to review “DIP Integrated Circuit IC Socket”

You must be logged in to post a review.

There are no reviews yet.