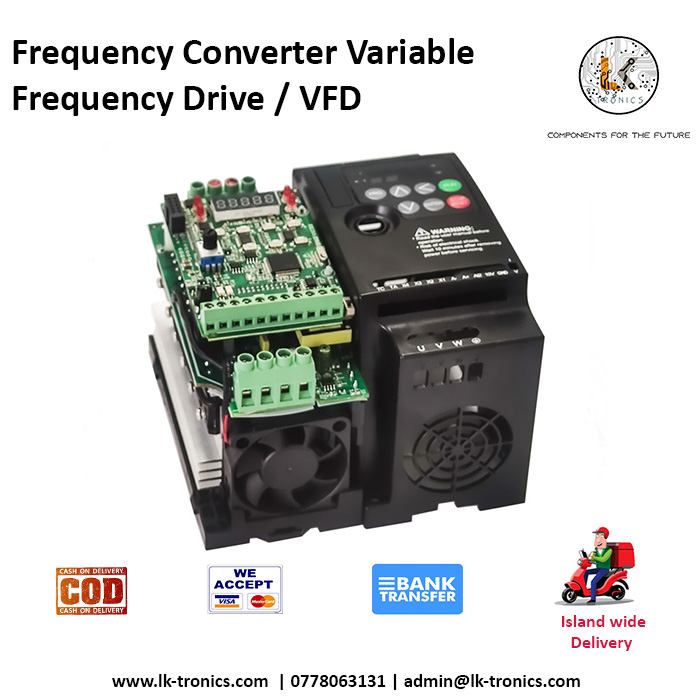

Frequency Converter Variable Frequency Drive / VFD

මෙම අයිතමය අපගේ වෙබ් අඩවියෙහි Shipping from Overseas

සේවාව යටතේ ගෙන්වන බැවින් මෙය ඔබ හට ලැබීමට

වැඩ කරන දින 10 – 20 පමණ ගත වේ.

මෙම අයිතමය ඔබ ඇනවුම් කල පසු මෙහි සියලුම යාවත් කාලීන කටයුතු e-mail මගින් සිදු කෙරේ

ස්තූතියි!

Compare

Frequency Converter Variable Frequency Drive / VFD

- is customized: None

- Output Current: 1.5-7A

- Output Frequency: 0-600Hz

- Weight: 1kg

- Size: 220*130*160

- Output Type: triple

- Output Power: 0.4/0.75/1.5/2.2kw

- Model Number: A10

- Type: DC/AC Inverters

- Brand Name: anxinee

- Origin: Mainland China

- Certification: CE

Quick selection instructions:

2、 In some countries, industrial power consumption is three-phase 380v, but most small power AC motors support star angle connection conversion, which means that a three-phase 380v motor with star connection can be converted to a three-phase 220v motor with triangle connection, so that it can be safely adapted to frequency converter speed regulation. The star angle conversion method can be referred to the following figure:

3、 If the motor is not marked with a convertible connection or the three-phase 380V itself corresponds to a triangular connection, it cannot be converted. Please purchase a three-phase 380V converter or use a single-phase 220V to three-phase 380V boost converter;

4、 Please select a suitable frequency converter and corresponding control method based on the type of load. The overload capacity of the motor in a short time is generally higher than that of the frequency converter. When the load is large (reaching or exceeding the rated current of the motor), please select a frequency converter with a higher power level or two levels.

(Note: Please change the voltage level corresponding to the connection method based on the motor nameplate.)

A10 series frequency converters are the main model of our company, with a power range of 0.4KW-132KW and a voltage level of 220V/380V. Based on our accurate understanding of customer needs, we adhere to the consistent pursuit of high quality and reliability of the product, constantly updating and iterating to pursue more accuracy and stability. Strong functions ensure a wide range of application of the product, and excellent performance verifies the excellent service life of the product.

Product features:

1、Hardware——Regardless of cost, do not cut corners, ensure quality, extend life, and support the following functions:

- Output short circuit protection

- Controllable cooling fan

- 5-bit LED display

- RS485 communication

- Input and output: 4 digital inputs, 1 analog input, 1 analog output, and 1 relay output.

- Mini model: Small size, convenient installation, and comprehensive functions.

2. Software——with multiple iterations and powerful functions, it is suitable for various complex situations and supports the following functions:

- Automatic carrier frequency

- Control mode switching

- Automatic torque increase

- Simple PLC programming

- 16 section speed operation

- PID closed-loop control

- Automatic current suppression

- Dynamic overvoltage suppression

- Regulated output

- Fast current limiting

- Shock suppression

- Instantaneous stop

- VF separation control

- 9 main and auxiliary frequency sources

- Frequency source superposition operation

- Frequency resolution 0.01 hz

- Multiple protection functions: phase loss, overcurrent, overvoltage, undervoltage, overheating, overload.

(Note: For more features and specific introductions, please contact us for an electronic version of the product manual.)

3. Product application

- In some specific situations, A10 series frequency converters can completely replace the following equipment: speed reducers, soft starters, energy-saving devices, voltage regulators, phase converters, and forward and reverse switching devices

- It can be used in the following scenarios: fan speed regulation to reduce noise, water pump constant pressure water supply, air compressor frequency conversion energy-saving transformation, injection molding machine frequency conversion energy-saving transformation, oil pump frequency conversion energy-saving transformation, conveyor belt real-time speed regulation, ball mill multi-stage speed operation, slow start of lifting equipment, etc.

>> Product wiring

Parameter setting description::

Using an external potentiometer to set parameters: F0-03 Set 2

Use the external start/stop switch to set parameters: F0-02 Set 1

Restore factory settings Parameters: FP-01 Setting 1

(Note: The mini machine does not have a braking unit. If you need a braking function, please select a G type VFD.)

>> Product Details

- Three-proof paint treatment, dust and moisture prevention

- Support external keyboard, flexible debugging and installation

- DC multi gear fan for more efficient heat dissipation

- Flame retardant housing, safe, sturdy and durable

>> Product dimensions and standards

1、Outline dimension drawing of product(Supports standard 35mm rail installation.)

2、Operation panel and opening size

3、Product Technical Standards

4、Product standard wiring

>> Product Use

Matters needing attention:

-

Frequency Converter Variable Frequency Drive / VFD The default maximum frequency of most motors is 50Hz, and the factory default frequency converter is 0-50Hz stepless speed regulation. Do not change the frequency range to increase it. For variable frequency motors, please refer to the frequency range marked on the motor nameplate;

-

Ordinary three-phase AC motors use frequency converters. When operating at low speeds for a long time, please pay attention to the heating condition of the motor, and install external heat dissipation devices if necessary;

-

There is a large leakage current during the operation of the frequency converter, which may prevent the leakage protector from working properly and cause frequent trips. The input line of the frequency converter needs to be rewired to bypass the leakage protector;

-

It is recommended that the output end of the frequency converter be directly connected to the motor, and there should be no switches or contactors between the frequency converter and the motor, except for changing the frequency of the star delta starting circuit;

VISIT OUR FACEBOOK PAGE FOR MORE INFO | MORE PRODUCT IN OUR SHOP

Based on 0 reviews

Be the first to review “Frequency Converter Variable Frequency Drive / VFD”

You must be logged in to post a review.

There are no reviews yet.